To Innovate is Possible by Everyone in Waterproofing

After the obligation of thermal insulation in the new buildings in the 2000s, the construction chemicals industry growth accelerated rapidly. In the last 5 years, waterproofing has also gained importance with the effect of the relevant regulations. In addition, global natural, sustainable and hygiene trends in building designs have been affecting interior and exterior applications. For example, the increase in the consumption of ceramic and granite coverings (larger size and porcelain), which are natural, hygienic, easily produced and therefore widespread materials, have led to an increase in the variety of products used with ceramic/granite applications and a higher performance expectation.

To describe the market size and importance for our country; Today, we see that there is still no precise waterproofing in 15 million residences in our country and that approximately 6 million m2 of buildings are at risk for earthquakes. In order to prevent corrosion, which shortens the life of buildings caused by water and increases the risk of collapse of buildings in an earthquake, it has been becoming imperative to apply the right products according to the right standards and to have an effective control system in place along with the relevant regulations.

When we examine widespread products in waterproofing, in Turkey, the Middle East and European countries, construction chemicals consumers prefer acrylic-cement-based, flexible 2K waterproofing membranes in wet areas, terraces, elevator shafts, swimming pools, due to their cost, performance and long-term durability. The relevant norm for quality assessment is the Turkish and European quality standard TS EN 14891: 2017, which is valid for waterproofing products applied in liquid form. These standard measures the water impermeability, adhesion strength after various conditioning and crack bridging ability of the related products.

In our point of view, there are 2 ways in front of Construction Chemicals manufacturers in the developing and competitive waterproofing market. The first way is to differentiate according to needs with high quality, service and different business models and the second way is to stand out from price competition by deeply understanding the market and related customer needs with the most appropriate cost and quality optimization. The 2 options, that can be applied together for different products/segments, are actually based on understanding the changing needs (behind reasons, substituent products, competition etc.) sustainable quality and differentiation. These cannot be carried out effectively with traditional R&D activities, because of their dynamic process. Here, designing innovation processes according to the company (to identify relevant problems and fulfil the needs exactly) has the potential to contribute significantly to manufacturers and various consumers. It will also make a difference if the relevant innovation team is formed from a highly motivated team with various expertise and perspectives.

In the front end of the innovation process, at the interview, observe and learn phase, which is crucial as a starting step of the methodology, the problems and expectations experienced by the relevant manufacturers, consumers and users in existing solutions are clearly identified. For acrylic-cement based 2K waterproofing products, issues such as adhesion to concrete, crack bridging, flexibility, delivery times, low VOC, pre/post-sales technical support, quality standard, and sustainable content are considered as components that positively or negatively affect the value offered.

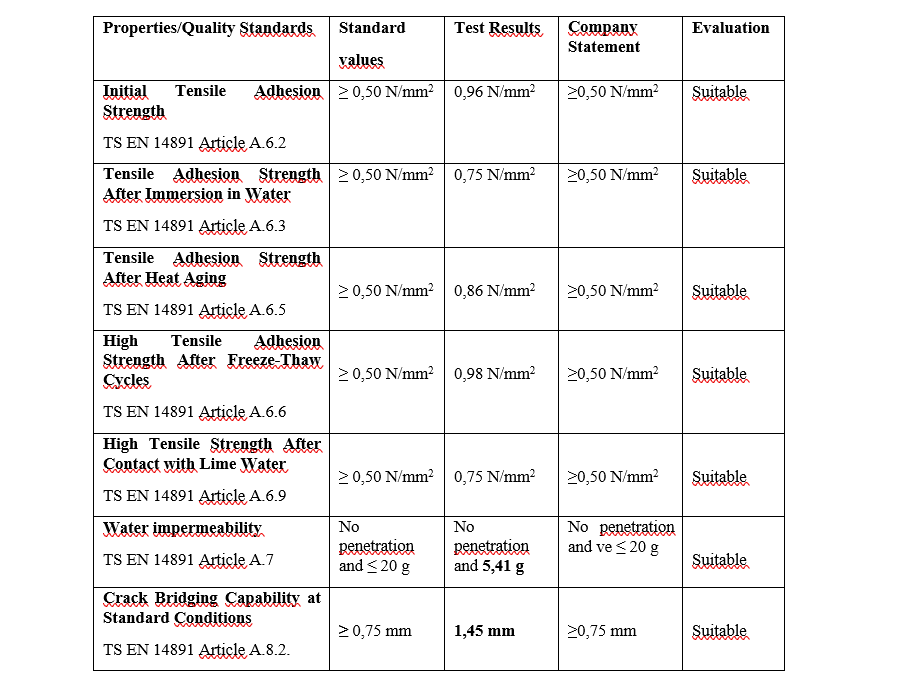

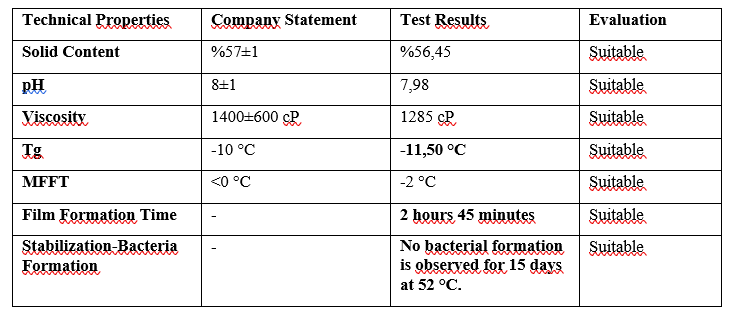

In order to highlight related expectations and needs of different customer groups, the detailed quality test results of our Ippol SC 6000 product within the scope of TS EN 14891 have been tried to be interpreted in terms of possible expectations of product developers, manufacturers, masters and contractors, end consumers:

ALV Kimya IPPOL SC 6000 Liquid Acrylic Dispersion Test Results

2K (Cement-Acrylic) Semi-Elastic Waterproofing Membrane Test Results and Comments

Comments:

- The adhesion strength values, in this table, represent the adhesion performance of the products on concrete surfaces after different conditioning. It can also be considered as the adhesion strength performance after the ageing of the product. This performance criterion is important for the end consumers and contractors mostly.

- Film formation time and low Tg values are directly related to the workability of the products at room temperature during application. The fact that this product has a minimum of 2 hours of pot life in the bucket and that it is easy to apply to the surface with a brush is especially valuable for masters and producers.

- The crack bridging value under standard conditions also gives a clue about the flexibility and durability of the product. Crack bridging value is measured for top-quality products both under normal conditions and at -20 °C. This performance value is crucial for every customer group, especially for the producer and the end consumer.

- The water impermeability test is the property that the product does the main job for each customer type. In TS EN 14891, it is generally defined as positive pressure water resistance, and when the product is exposed to pressurized water from the back, negative pressure resistance is measured. In this test, the consumption and application thickness declared by the manufacturer and formulation may cause whether or not pass the test. Therefore, it makes a difference if it is tested regularly by the manufacturer.

- Another important test is the suitability test for drinking water tanks. It is necessary for use in drinking water tanks that the raw materials used in the related products do not contain chemicals that will harm the drinking water.

In a nutshell, Quality, standard norms and R&D processes are not enough to deeply understand the changing needs of different segments Today and in order to differentiate in competition, it is necessary to design the relevant innovation processes (by the manufacturers, according to their own needs) and proceed with the focuses of jobs to be done and customer benefits. Thus, in the construction chemicals sector, where competition is increasing day by day, the products, services and business models offered by the manufacturer to the market will be transformed into deserved values.